January 2016

We now have hot water

13/01/16 17:50

Stuart, from Sunamp, and Dan, from Solarcache, installed the Sunamp PV units today. Apart from the challenge of getting the 85kg units from the ground floor to the first floor in the absence of any stairs the installation went without a hitch. We had just about left sufficient space for the units and the Plant Room is now effectively finished apart from second fix electrics. Mind you it will be months before any doors for the Plant Room are designed, built and installed - a minor detail. The units, working in parallel, takes advantage of surplus electricity that would otherwise be exported to the grid - this will the main source of hot water for the summer months. In Winter the plan is to 'boost' the units with Electricity 7 night time supply and use whatever surplus solar PV to counter the small standing losses from the units. The photo below shows the two units with the two matching SolarCache throttles above. The copper pipework is all 15mm copper with a mix of crimped and compression fittings. The two SolarCache throttles have still to be permanently wired in and there is no insulation yet on the hot water supply pipes from the Sunamp units.

This system does depend upon surplus solar PV which shouldn't be much of a problem as long as the system performs correctly which, of course, it isn't.

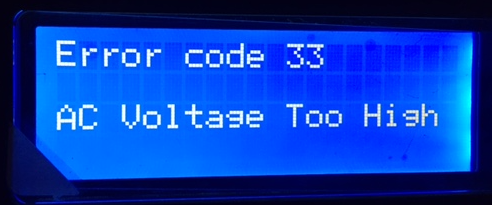

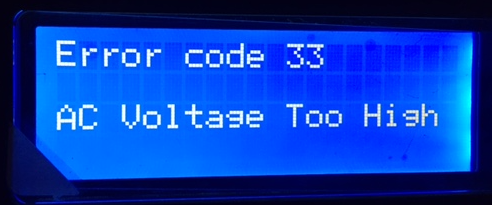

It would appear the grid voltage is slightly out of specification and as soon as the Inverter gets above 253 volts it trips out and we then lose generation until it cuts back in. The supply from the grid should never be above 253 volts and, even being generous for voltage drops (from inverter data) it must be frequently get above 254 volts. Electricity North West paid a visit and they measured 252volts at the supply - they have ordered monitoring equipment - hopefully they will then adjust down the voltage and everything will be fine,

Slightly better news from the second air test - we are now at 0.66 air changes on the depressurisation test. Pretty close to the Passive House limit but we have further work to do on the build which should further reduce the losses. We still need to improve the losses from then installation of the rear door and windows but we anticipate Ecohaus Internorm making these changes when the rest of the internal work is complete.

Elsewhere work on the extended and rebuilt front canopy has started. The destruction of the old one only took a few hours. Pegasus have also managed to apply a colour coat to the rear offset - only the top texture coat now needs to be applied and then the 'above-ground' insulation is complete.

Rob and Dave have now boarded out most of the first floor so we are getting a better feel for how the rooms will look. The plumbing continues with the Geberit frames installed and framed although Soil Pipe connections still need to be completed

This system does depend upon surplus solar PV which shouldn't be much of a problem as long as the system performs correctly which, of course, it isn't.

It would appear the grid voltage is slightly out of specification and as soon as the Inverter gets above 253 volts it trips out and we then lose generation until it cuts back in. The supply from the grid should never be above 253 volts and, even being generous for voltage drops (from inverter data) it must be frequently get above 254 volts. Electricity North West paid a visit and they measured 252volts at the supply - they have ordered monitoring equipment - hopefully they will then adjust down the voltage and everything will be fine,

Slightly better news from the second air test - we are now at 0.66 air changes on the depressurisation test. Pretty close to the Passive House limit but we have further work to do on the build which should further reduce the losses. We still need to improve the losses from then installation of the rear door and windows but we anticipate Ecohaus Internorm making these changes when the rest of the internal work is complete.

Elsewhere work on the extended and rebuilt front canopy has started. The destruction of the old one only took a few hours. Pegasus have also managed to apply a colour coat to the rear offset - only the top texture coat now needs to be applied and then the 'above-ground' insulation is complete.

Rob and Dave have now boarded out most of the first floor so we are getting a better feel for how the rooms will look. The plumbing continues with the Geberit frames installed and framed although Soil Pipe connections still need to be completed

More December Progress

02/01/16 13:40

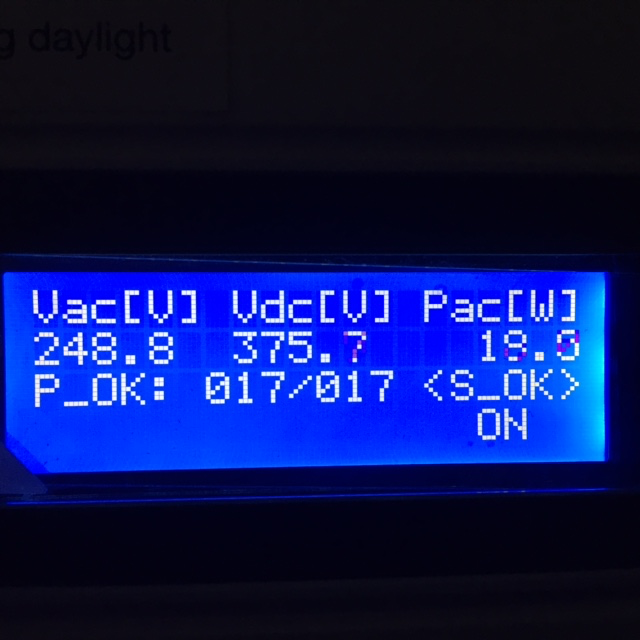

The site shut down for a two-week Christmas break on the 18th of December. Prior to this the main highlight was the commissioning of the solar PV system on the 17th. This enabled us to complete the Feed in Tariff application before the small reduction in rate which came into effect of the 1st January. Even more important was that we avoided the drastic reduction in tariffs effective from January 14th. The photo from the inverter shows we were producing 19 watts just before sunset on the 17th December - it also shows the inverter has found the 17 Solar Edge optimisers.

On a less optimistic note we had the first air test in mid December and this revealed a 0.78 air change figure. Liam and Chris were hoping to hit a maximum of 0.6 air changes on the first test. At least this test revealed the main areas that needed additional work and that the doors and windows also needed further adjustment. Given the lack of plaster on many surfaces, the work still required on the front elevation and the lack of external render on most faces the team are confident of achieving the Passive House 0.6 air change maximum. Air tightness 'guru' Paul Jennings below checking his instrumentation.

I spent most of a day adding extra insulation to the air supply and air extract ducts (photo below taken before I added extra Armaflex to the Intake Duct Heater). I simply used materials that were surplus to the MVHR install. After doing this I fed the new data into PHPP and eagerly awaited the result - about 12kW/a. So I will save about £2 per year from my efforts - if I had undertaken the calculation first I doubt that I would have bothered!